Click here to learn about and purchase Bare-Metal® Foil Click here to learn about and purchase Bare-Metal® Foil

Click here to read about and purchase the Bare-Metal® Panel Scriber Click here to read about and purchase the Bare-Metal® Panel Scriber

New 9 hour DVD series New 9 hour DVD series

"Creating an Artificial Water Splash"

Click here for Polytek® Mold Making Rubber Compounds Click here for Polytek® Mold Making Rubber Compounds

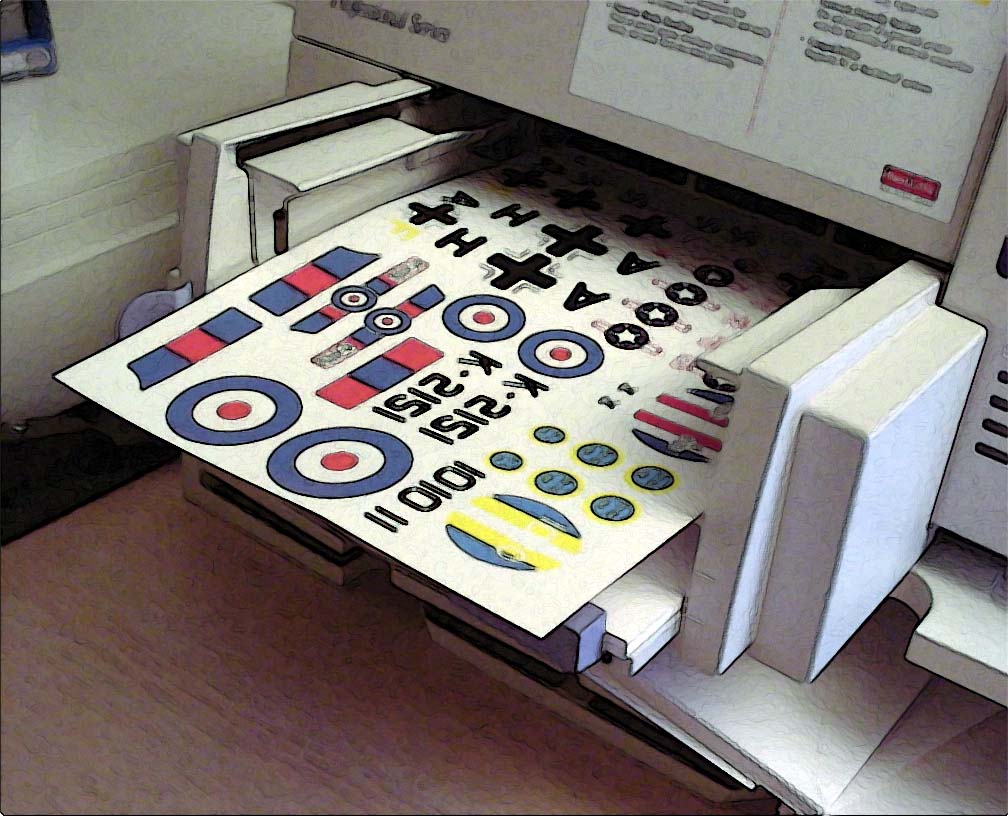

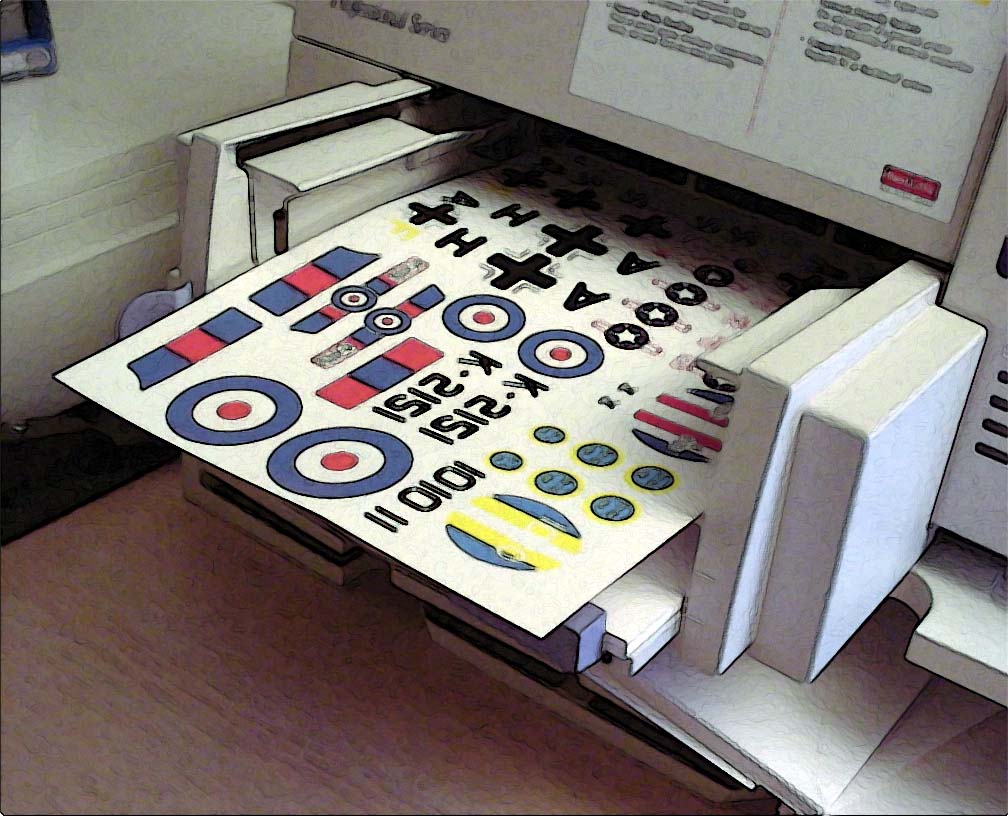

Click here to purchase Click here to purchase

Experts-Choice® Decal Film

Click here to read about making concrete stamps using Polytek® 75-80 Polyurethane Rubber Click here to read about making concrete stamps using Polytek® 75-80 Polyurethane Rubber

|

Polytek® Silicone Rubber, Polyurethane Rubber,

Latex Rubber, and Alginate

Many of the mold making systems produced by Polytek have crossover potential, meaning they are not limited to the described possible uses listed on this page. We are only providing the following list as food for thought. If you need assistance choosing the right mold material for your application please give us a call at 800.628.7296.

Silicone and Polyurethane mold rubbers can be used to make candle molds, soap molds, cold cast bronze sculptures, concrete and plaster casts, wax casting for foundry and jewelry lost wax process, casting polyurethane, epoxy and other resins.

Silicones are especially good for their self-releasing characteristics. Which means that casting resins will not stick to the rubber after it is cured. Also, for many applications silicone will out live polyurethane mold materials. Silicones are preferred by rapid prototypers for their ease of use and predictable accuracy. Hobbyists also enjoy silicones because many silicones have shorter curing times.

Polyurethane rubber molds are great for concrete molds and stamps, plaster casting or other applications that involve high abrasive materials. Polyurethane molds are often used for architectural restoration, taxidermy, and artists in a wide range of applications where making repeated copies is important.

Latex rubber is popular with artists doing statuary pieces in either plaster or concrete. Latex is a tough natural rubber that can produce high surface detail.

Alginate mold material is usually a one time use product. It is safe for skin contact with most subjects. Plaster or other gypsum casting media are generally used with alginate mold compounds.

PLATSIL SERIES SILICONE MOLD MATERIALS

Polytek Platsil 71 Series Silicone RTV is a platinum cured system. Includes Polytek 71-20 our most popular 1:1 by volume catalyzed silicone RTV and new Polytek 71-15 and softer version of 71-20. And many other products, from very soft 71-10 to firm 71-60 hardness. Best for casting resins and low melting metals.

TINSIL SERIES SILICONE MOLD MATERIALS

Polytek Tinsil 70 Series Silicone RTV is a tin cured system. And many other products, from very soft 70-10 to firm 70-60 hardness. Best for casting resins and low melting metals.

Poly 74

Great line-up of high quality rubber for foundry, concrete forms, concrete stamping pads, and statuary mold making materials. Full tables and prices. Complete How To section.

Poly 75

Great line-up of high quality rubber for foundry, concrete forms, concrete stamping pads, and statuary mold making materials. Full tables and prices. Complete How To section.

Latex Molding Compound

Poly Latex 60 mold making compound. Great for making cast concrete items. Very easy to use one part mold rubber, just brush on and allow to dry.

False Face Casting Latex

Casting Latex is commonly used for making masks, cast parts for movie and theatre actor make-up parts, and other cast rubber objects

PolyGel Self-Thickening Polyurethane Rubber

PolyGel series of self thickening liquid polyurethane materials. Includes a choice of brushable mold material.

Alginate

A natural water activated mold making compound. The perfect choice for making molds of the human body. Lifecasting is made easy with Polytek's Hydrogel® N.

Release Agents, Bronze, and Glass Fillers

Silicone and Wax based mold release agents. Light and dark bronze filler for cold cast bronze. Micro bulb and solid glass sphere fillers to displace resin volume. Micro bulbs make cast pieces lighter. Solid glass spheres make castings heavier.

Click image to enlarge |

Click image to enlarge |

Click image to enlarge |

Click image to enlarge |

. |